Urethane, a highly versatile resin discovered almost a century ago, is a very widely used substance that is being utilized in projects as small as art and craft to projects as big as industrial manufacturing lines. Urethane is mostly used to produce plastic components. It can be used to manufacture items which are flexible in nature as well as which are quite rigid.

Urethane Casting is a great low-cost and high-quality way of producing various components and models which can incorporate a high level of detailing and finish. The process of Urethane Casting involves pouring the urethane into a mould and letting it cure. Even though the process sounds straightforward, it can be tricky to get good results, and if performed by untrained professionals, it can lead to poor end products. Therefore, choosing the right company for Urethane Casted Products is very important.

Urethane Casting Process Steps

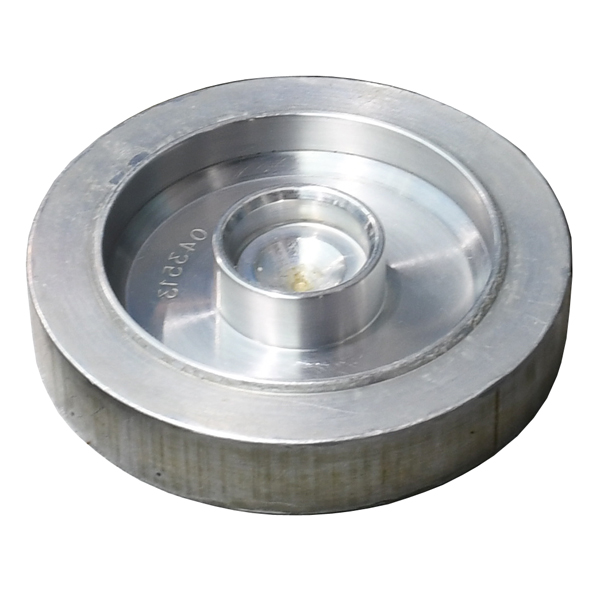

- Aluminum Mould: The first step is to create an aluminum mould which is used for curing the urethane. At Nuraseal we CNC Machine the aluminum moulds in-house, depending on the production requirements multiple sets of moulds are produced.

- Mixing Urethane: The second step involves mixing the urethane liquids and any additives and colour pigmentation which initiates the chemical reaction turning urethane from liquid form to solid form. This process is called curing.

- Pour the Mixed Urethane into the Mould: The final step is to pour the urethane into the aluminum mould and allow the urethane cure. You must let the urethane to cure for at least one hour so that it is properly cured.

- Once the initial curing of the urethane is complete, the parts are removed from the aluminum moulds and further cured. Parts then have flashing removed and are quality inspected and finally packaged.

Benefits of Urethane

Urethane parts offer several benefits, some of which include:

- Suitable when high-quality components are required but at a lower volume.

- Urethane offers freedom of design, and products produced through urethane casting are highly precise.

- Very short lead times

- Offers a range of finish, flexible and rigid, as required by specific application

- The shrinkage rate is very low compared to other processes

- It can be FDA approved when the components are required for food and medical industry purposes.

Urethane Casting by Nuraseal

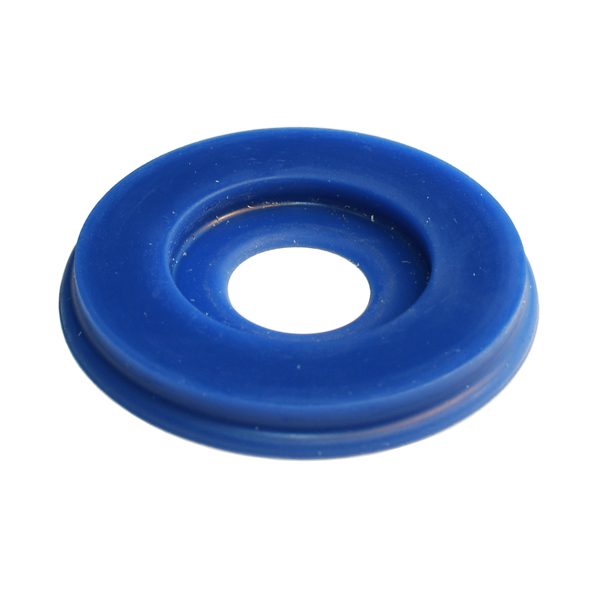

Nuraseal manufactures a wide range of urethane seals, which includes symmetrical U-cup, loaded seals, thin-lip U-cups, dual-durometer U-cups and many other custom profiles. Seals are available in both imperial and metric sizes with more than 1200 moulds in stock for large diameter U-cup seals up to 32½” OD and in-house manufacturing capabilities to produce custom moulds and seals up to 34″ OD. Seals are available in a wide range of polyurethane moulding materials and offer high tensile strength, excellent abrasion resistance, and superior pressure resistance up to 5000 psi.

If you are looking for high-quality and precise urethane seals (including standard & custom profiles) for your industrial applications, contact the Nuraseal team now. Our expert team can provide application support and manufacture seals for you to meet and exceed your expectations in a very short turnaround time. Moreover, if you are interested in custom part numbering and private branding, our team will handle it for you.