Cast Urethane

Manufacturing a wide range of large diameter cast urethane seals including standard symmetrical U-cups, loaded seals, thin-lip Ucups, dual-durometer U-cups and custom profiles such as feathered and asymmetrical lip designs. Seals are available in both imperial and metric sizes with more than 1200 molds in stock for large diameter U-cup seals up to 32½” OD and inhouse manufacturing capabilities to produce custom molds and seals up to 34″ OD. Seals are available in a wide range of polyurethane molding materials and offer high tensile strength, excellent abrasion resistance, and superior pressure resistance up to 5000 psi.

Polyurethane Seals

A wide range of precision cast urethane sealing products custom manufactured in-house to meet the demanding needs of your applications. We offer a broad range of products and profiles in both inch and metric sizes including U-cups, rod wipers, piston cups, and V-pack sets.

All of our polyurethane products are manufactured from high-grade polyurethane compounds to ensure that final quality of our end-products is tough enough to meet and exceed the needs of your applications.

Polyurethane Large Diameter Seals

A wide range of large diameter urethane seals including standard symmetrical U-cups, loaded seals, thin-lip U-cups, dual-durometer U-cups and custom profiles such as feathered and asymmetrical lip designs. Seals are available in both imperial and metric sizes with more than 1200 molds in stock for large diameter U-cup seals up to 32½” OD and in-house manufacturing capabilities to produce custom molds and seals up to 34″ OD. Seals are available in a wide range of polyurethane molding materials and offer high tensile strength, excellent abrasion resistance, and superior pressure resistance up to 5000 psi.

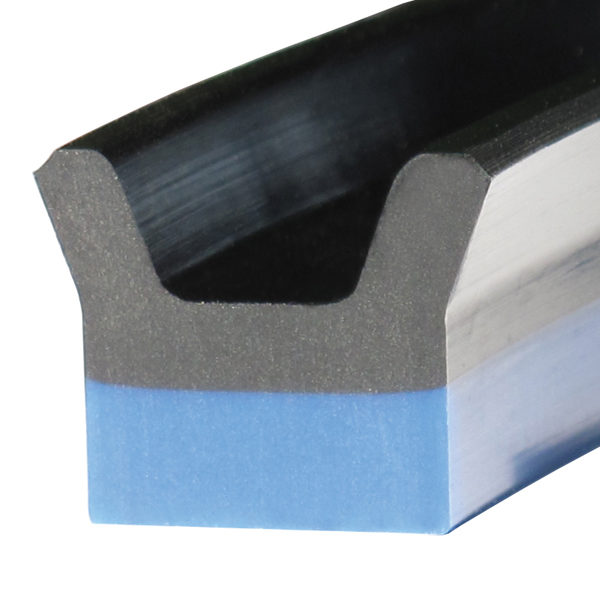

Dual-Durometer Seals: 10,000 psi Service

A custom dual-durometer seal which features a 70 Shore D base material chemically bonded to a standard lip material. This unique construction allows for increased extrusion resistance at the base with excellent sealing capabilities at the lip and service loads up to 10,000 psi. Depending on your particular application, alternate materials are available with custom colors and branding of your parts.

Application Support

Whether you require technical support, drawings or just some general information about seals and sealing materials, we will be able to help you with your questions. We offer flexible, fast and convenient solutions for sealing applications.

An unlimited range of special and custom profiles manufactured exactly according to specifications in a wide range of standard and custom materials. We provide drawings, technical expertise and we manufacture samples and working prototypes within five days or less.

Bumpers, Wheels and Special Products

Custom manufacturing capabilities for molding polyurethane into a wide variety of specialized products including bumpers, wheels, flanges, bushings and scrapers. Ask us about our range of options supported by in-house tooling, custom part numbering and material alternatives as required.

In-House Tooling

Our computer-aided design system means faster manufacturing, production and turnaround times. In-house tooling decreases pre-production lead times and helps manage overall tooling costs. It also facilitates making adjustments on-the-fly to ensure that tolerances are met and quality is guaranteed. Our expertise and experience allows Nuraseal to spend more time making your products, and less time waiting for tooling.