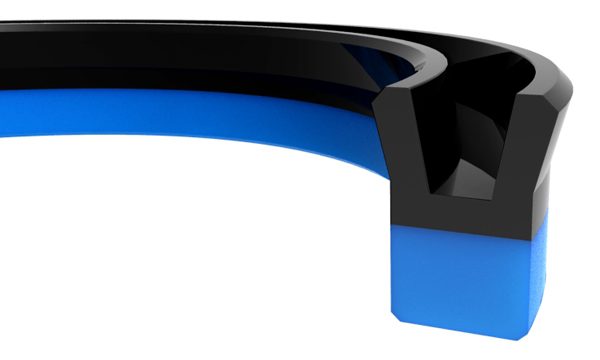

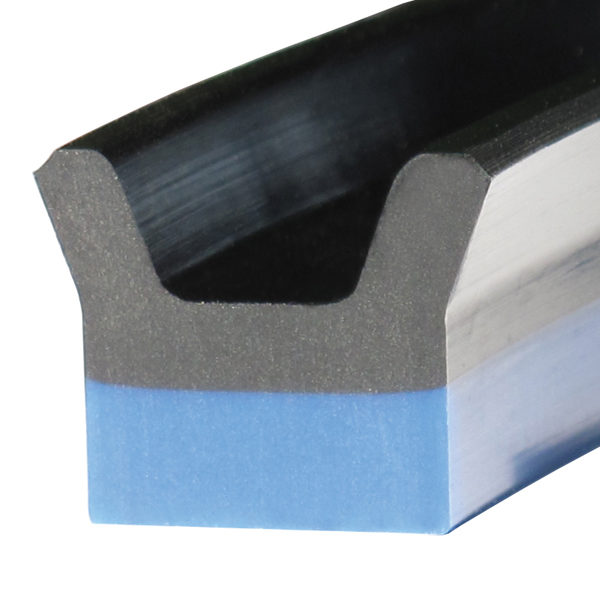

Dual-Durometer Seals: 10,000 psi Service

A custom dual-durometer seal which features a 70 Shore D base material chemically bonded to a standard lip material. This unique construction allows for increased extrusion resistance at the base with excellent sealing capabilities at the lip and service loads up to 10,000 psi. Depending on your particular application, alternate materials are available with custom colors and branding of your parts.

Quality Polyurethane Materials

The custom duo-durometer seal features a 70 Shore D base material chemically bonded to a standard lip material. This unique construction allows for increased extrusion resistance at the base with excellent sealing capabilities at the lip. Our standard polyurethanes offer high tensile strength, excellent abrasion resistance, unlimited shelf life, excellent hydrolytic stability, pressures up to 5,000 psi and service temperatures up to 200°F. Our standard material is a thermoset, polyester type polyurethane available in two durometers: 92 ShoreA and 95 ShoreA.

Advantages of Polyurethane

- Extremely durable - resists abrasion, cutting, tearing and shearing

- Superior tensile strength

- Excellent shelf life - will not harden or crack over time

- Excellent impact resistance and quick rebound - well suited for high frequency vibration applications

- Highly resistant to cracking under repeated flexing in both hot and cold conditions as well as applications subjected to thermal shocks

- Resists swelling and deterioration in water applications up to 70°C (158°F)

- Resists radiation and ozone deterioration - well suited for nuclear applications

In-House Tooling

Our 3D CAD systems mean faster prototyping and manufacturing turnaround times. With in-house tooling facilities, we are able to further decrease production times and manage tooling costs. For all custom parts, we can produce samples in as little as 24 hours which are actual molded parts identical to any future production runs.