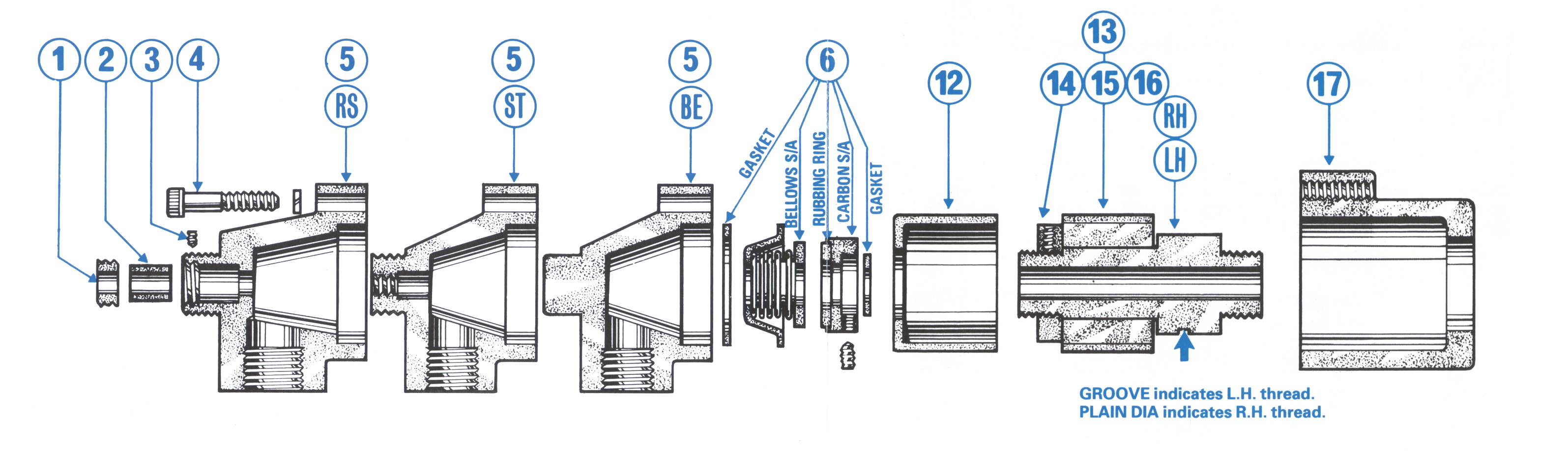

Filton® Rotary C.B. Union - High Temperature

(Sizes 1/4" to 1-1/4")

Maintenance and Overhaul

- Remove bolts and washers (4) which allow for the removal of the adapter (5) and body (11).

- Remove the bellows subassembly and the gasket of the seal kit (6).

- Remove locking screws and unscrew the carbon subassembly (R.H. thread) of the seal kit (6).

- Remove the spacer (7).

- Thoroughly clean and check the ball bearing kit (9). Re-lubricate using an approved grease. If there is any doubt about the bearing condition, replace it by removing circlip (8) and then pressing-off the bearing kit.

- If the adapter (5) is Type R.S., remove the locking screw (3), unscrew the locking ring (1) and remove the C/T bearing (2).

- Replace seal kit (6), bearing kit (9) and if Type R.S., C/T Bearing (2). Handle the seal kit with care to avoid damaging the lapped seal faces.

- Thoroughly clean all parts before reassembly (which is virtually the reverse of the above steps).

- After reassembly, follow the recommended installation procedures and allow for a suitable run-in period to ensure the seals are working correctly before refitting to the machine.