Material Options

At Nuraseal, our polyurethanes offer high tensile strength, excellent abrasion resistance, unlimited shelf life, excellent hydrolytic stability, pressures up to 5000 psi and service temperatures up to 200°F. We utilize two main categories of elastomeric materials: liquid-cast thermoset ployurethane and injection-moulded thermoplastic polyurethane.

Thermoset Polyurethane

- Exhibits excellent wear resistance, toughness, tensile strength and cut resistance.

- Good fluid compatibility over a broad temperature range.

- Highly resistant to ozone and radiation.

- Available in hardness ranging from 60 ShoreA (rubber) to 85 ShoreD (hard plastic).

- Shelf life is virtually unlimited.

- Custom colours are easy to compound with minimal set-up or lead time.

- Can be compounded with various additives including PTFE, UHMW polyethylene and molybdenum disulphide.

- Parts can be manufactured for inexpensive tooling with minimal set-up costs.

- Prototyping and lower volume production runs are fast and economical.

Thermoplastic Polyurethane

- Exhibits good wear resistance, toughness, tensile strength and fluid compatibility.

- Compounds available for applications ranging up to 130°C.

- Available in hardness ranging from 80A to 70D.

- Available in a variety of colours.

- Production methods allow for large quantities to be manufactured economically.

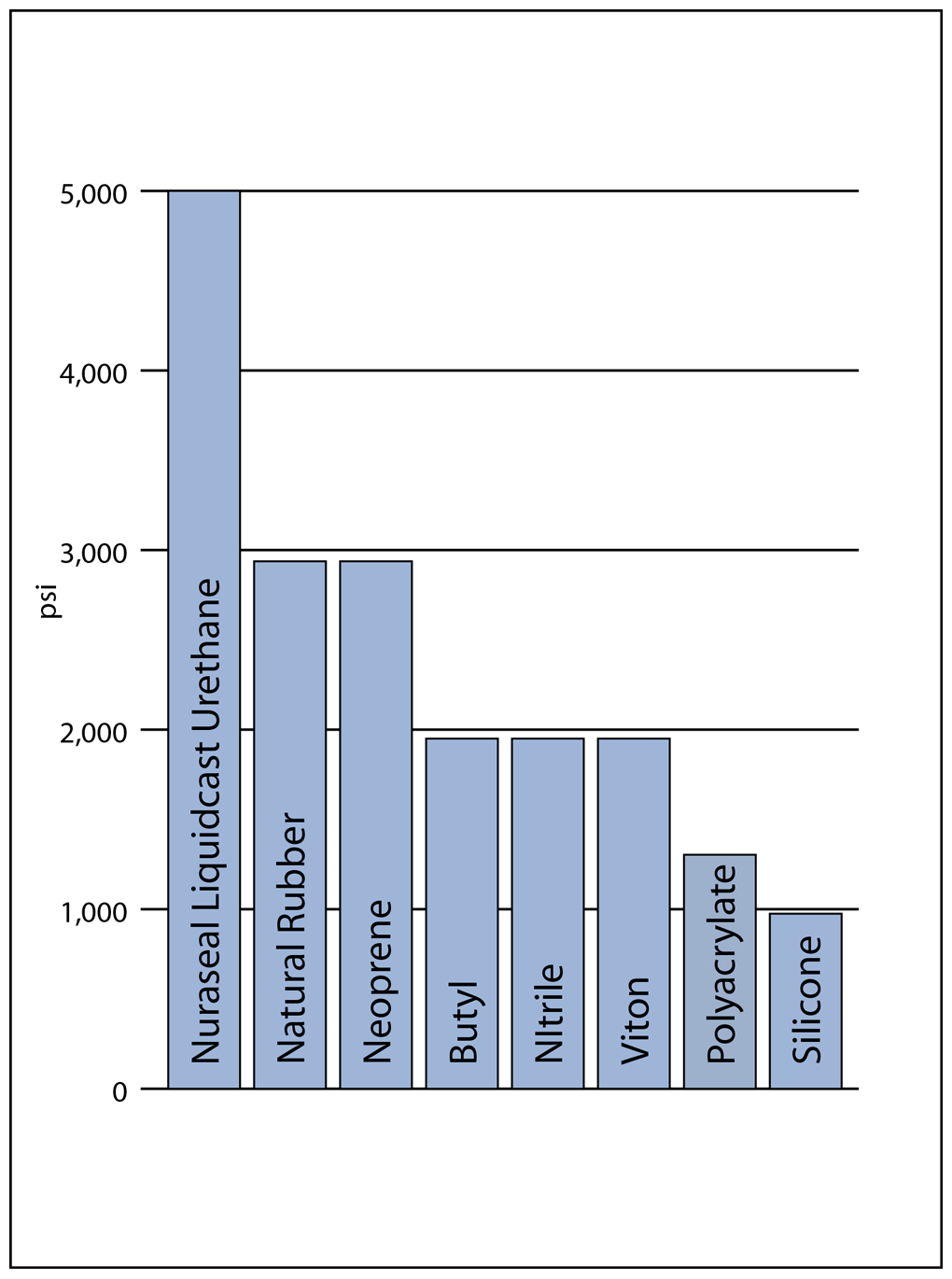

Tensile Strength of Common Elastomers

Depending on your particular requirements, other materials are also available. Please contact us for details.