Filton® Rotary R.E.B. Union

(Sizes 1-1/2" to 6")

Maintenance and Overhaul

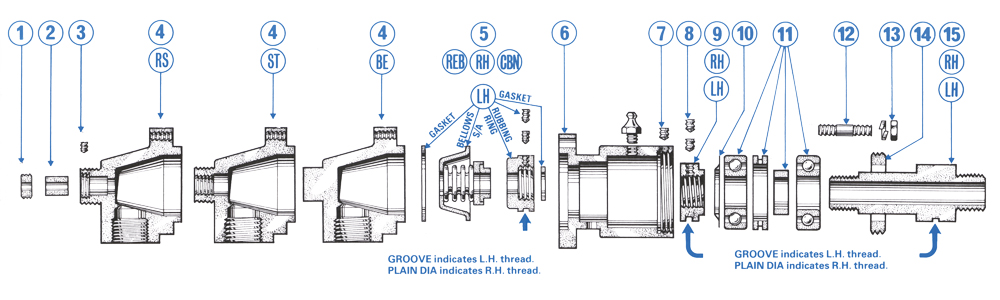

- Remove nuts (13) and washers which allows for the removal of adaptor (4).

- Remove bellows subassembly and gasket of seal kit (5).

- Remove locking screw (7) and unscrew locking ring (14 - RH Thread) and extract spindle (15) complete with ball bearings, etc.

- Remove locking screws from the rubbing ring of seal kit (5), unscrew the rubbing ring (RH or LH thread) and remove gasket.

- Thoroughly clean the ball bearing kit (11), check the condition of the bearings and re-grease. If there is any doubt about the condition, replace the bearing kit and pre-pack with an approved grease.

- To replace the bearing kit (11), remove locking screws (8), bearing locking ring (9 - RH or LH Thread) and Nilos ring (10). Press off the bearing kit.

- If the adaptor (4) is Type R.S., remove locking screw (3), unscrew locking ring (1 - RH Thread) and remove C/T bearing (2).

- Thoroughly clean all parts before reassembly (which is virtually the reverse of the above steps).

- Replace seal kit (5), bearing kit (11) and if type RS, C/T bearing (2). Handle seal kits with care to avoid damaging the precision lapped seal faces.

- Thoroughly clean all parts before reassembly (which is virtually the reverse of the above steps).

- After reassembly, follow the recommended installation procedures and allow for a suitable run-in period to ensure the seals are working correctly before refitting to the machine.

* Note: For the 125 (5”) and 150 (6”) models, there is a screwed

adjusting ring on the flanged end of the body which is locked with a screw and can be adjusted to give 6mm compression on the bellows subassembly if necessary.